Difference between revisions of "LCD-HD101"

From FriendlyELEC WiKi

(→介绍) |

(→关于一线触摸) |

||

| Line 41: | Line 41: | ||

|} | |} | ||

| − | == | + | ==One-Wire Technology== |

| − | * | + | * As for most ARM boards we observed that using CPU’s ADC conversion didn’t work very well for large-size LCDs (7” and larger) with four-wire resistive touch. Some vendors use an external USB or UART module to connect these LCDs. To save CPU’s hardware resources and minimize usage of external modules we developed the one-wire technology which only uses a single GPIO pin and we have integrated this technology in all our LCD controller boards. This technology uses an MCU to communicate with the touch panel’s chip (we use the ADS7843 chip or other chips compatible with ADS7843) and process the four-wire resistor’s analog signals and output the filtered stable signals to the ARM board via GPIO. We tested this technology in various LCDs and it worked very well even for a large LCD of 19” and some commonly observed issues such as screen flipping and jittering were not encountered. |

| − | * | + | * Today most LCDs whose size is less than 12” have LED backlight. We use the one-wire’s MCU to process the backlight as well. The backlight is set with a range of values. Users can set a value to the backlight and this value is passed to MCU for processing via one-wire’s GPIO pin. |

| − | * | + | * Each FriendlyARM’s LCD module has a unique ID which is saved in the one-wire’s MCU. When the MCU reads the ID information from GPIO signals it will recognize the LCD model and instruct the bootloader to load the corresponding LCD driver, making a FriendlyARM LCD plug and play. |

| − | * | + | * As for the one-wire technology for our LCDs with capacitive touch we removed the resistive touch panel’s chip but kept the backlight adjusting function and LCD’s ID information. Therefore the communication between the capacitive touch and the ARM board is still standard IIC. |

| − | * | + | * Attention: the one-wire technology is different from the commonly known single-bus communication. Actually in the ARM board we use a PWM timer (not PWM pins) to generate the communication frequency (9600Hz). For more details please refer to the driver’s source code. |

Revision as of 15:28, 28 June 2016

Contents

[hide]1 Introduction

- The HD101 LCD is a FriendlyARM developed LCD with capacitive touch panel. Its resolution is 1280 x 800. Its backlight is adjustable via FriendlyARM’s one-wire technology. It works with FriendlyARM’s Tiny4412, Super4412, NanoPC-T1, NanoPC-T2, NanoPi 2 and NanoPi 2 Fire under Linux and Android. Its driver is open source.

- The HD101 has a black ABS bezel with mounting holes making it easily deployed in various situations.

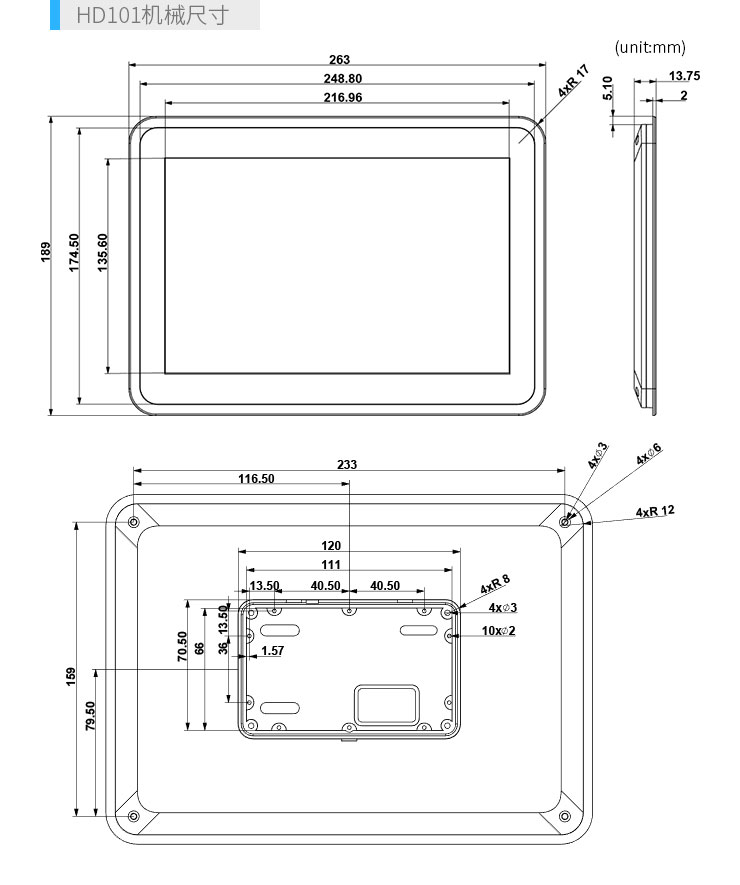

2 Dimensional Diagram

3 Applications

4 Datasheet

5 Schematics

6 Applicable Platforms

Debian Android Linux+Qt NanoPi 2 NanoPi 2 NanoPi M2 NanoPi M2 NanoPi 2 Fire NanoPi 2 Fire NanoPi M3 NanoPi M3 NanoPC T2 NanoPC T2 NanoPC T3 NanoPC T3 Smart4418 Smart4418 Tiny4412 Tiny4412

7 One-Wire Technology

- As for most ARM boards we observed that using CPU’s ADC conversion didn’t work very well for large-size LCDs (7” and larger) with four-wire resistive touch. Some vendors use an external USB or UART module to connect these LCDs. To save CPU’s hardware resources and minimize usage of external modules we developed the one-wire technology which only uses a single GPIO pin and we have integrated this technology in all our LCD controller boards. This technology uses an MCU to communicate with the touch panel’s chip (we use the ADS7843 chip or other chips compatible with ADS7843) and process the four-wire resistor’s analog signals and output the filtered stable signals to the ARM board via GPIO. We tested this technology in various LCDs and it worked very well even for a large LCD of 19” and some commonly observed issues such as screen flipping and jittering were not encountered.

- Today most LCDs whose size is less than 12” have LED backlight. We use the one-wire’s MCU to process the backlight as well. The backlight is set with a range of values. Users can set a value to the backlight and this value is passed to MCU for processing via one-wire’s GPIO pin.

- Each FriendlyARM’s LCD module has a unique ID which is saved in the one-wire’s MCU. When the MCU reads the ID information from GPIO signals it will recognize the LCD model and instruct the bootloader to load the corresponding LCD driver, making a FriendlyARM LCD plug and play.

- As for the one-wire technology for our LCDs with capacitive touch we removed the resistive touch panel’s chip but kept the backlight adjusting function and LCD’s ID information. Therefore the communication between the capacitive touch and the ARM board is still standard IIC.

- Attention: the one-wire technology is different from the commonly known single-bus communication. Actually in the ARM board we use a PWM timer (not PWM pins) to generate the communication frequency (9600Hz). For more details please refer to the driver’s source code.